Digital Twins in Action: Revolutionizing Drilling Operations for Efficiency and Safety

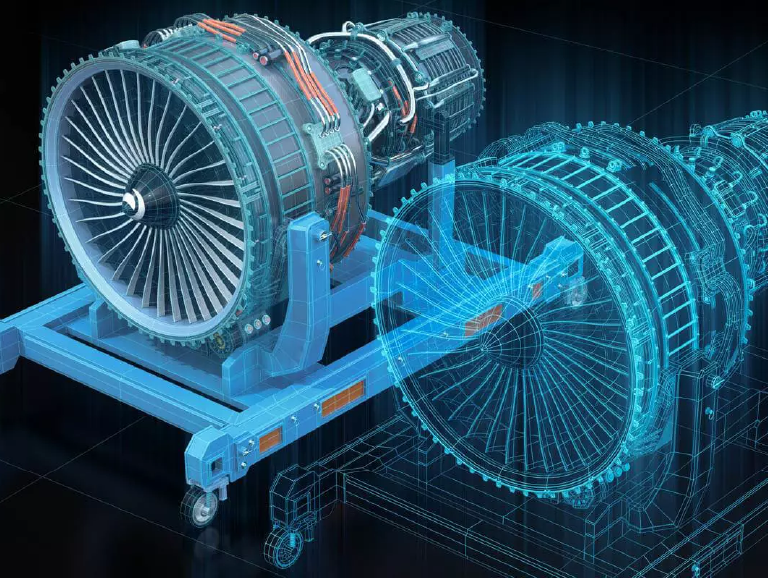

The oil and gas industry is rapidly evolving, and one of the most transformative technologies driving this change is the digital twin. A digital twin is a virtual replica of a physical asset or system, allowing companies to simulate, monitor, and optimize operations in real time. For the high-risk, resource-intensive world of oil and gas drilling, digital twins are providing groundbreaking solutions to improve efficiency, safety, and sustainability. This blog explores how digital twin technology is revolutionizing drilling operations and reshaping the future of the

industry.

Real-Time Monitoring and Data-Driven Decision Making

One of the most significant advantages of digital twins is their ability to provide real-time monitoring of drilling operations. By creating a virtual model of drilling rigs, wells, and associated infrastructure, companies can monitor every aspect of their operations continuously. This real-time data gives operators the ability to visualize how their equipment and systems are performing under current conditions.

For instance, by integrating IoT sensors, machine learning algorithms, and historical data into a digital twin, drilling teams can receive real-time feedback on equipment health, drilling progress, and environmental factors such as pressure and temperature. This data empowers operators to make informed, data-driven decisions that optimize drilling efficiency and minimize risks.

Enhancing Safety Through Predictive Analytics

Safety is a top priority in the oil and gas industry, especially in drilling operations where even minor failures can lead to catastrophic consequences. Digital twins help enhance safety by enabling predictive analytics. By continuously analyzing data from sensors on drilling rigs and other equipment, digital twins can identify early warning signs of potential failures.

For example, if a specific component on a drilling rig is showing signs of wear or unusual vibration patterns, the digital twin can flag the issue before it escalates. This predictive capability allows operators to schedule maintenance or equipment replacements proactively, reducing the likelihood of accidents, unplanned downtime, or costly repairs. This not only safeguards the workforce but also reduces financial losses from unscheduled interruptions.

Moreover, digital twins can simulate potential drilling scenarios to assess the risks involved. Teams can test different drilling strategies, evaluate the impact of environmental variables, and determine the safest approach to achieve operational goals. This proactive approach to risk management helps to mitigate potential hazards and ensure that safety protocols are adhered to at all times.

Optimizing Drilling Efficiency

Efficiency is another key area where digital twins are making a substantial impact. In traditional drilling operations, determining the optimal drilling path or method often requires trial and error, leading to wasted resources and time. However, digital twins enable companies to simulate multiple drilling scenarios virtually, providing insight into the most efficient and sustainable methods before any physical drilling occurs.

These simulations allow teams to test various drilling paths, assess the effectiveness of different techniques, and predict the outcomes of each scenario. By identifying the optimal approach in advance, digital twins help minimize resource consumption, reduce energy usage, and lower costs. This leads to faster drilling times and maximized productivity, ensuring that companies extract resources more efficiently while minimizing their environmental footprint.

Reducing Environmental Impact

The oil and gas industry is under increasing pressure to reduce its environmental impact, and digital twin technology is playing a pivotal role in driving sustainability. By optimizing drilling efficiency, digital twins contribute to reduced energy consumption, lower emissions, and less waste.

Additionally, digital twins can be used to model the integration of renewable energy sources into drilling operations. For example, companies can simulate the potential use of wind or solar power to complement traditional fossil fuel operations, creating hybrid energy strategies that reduce the overall carbon footprint. This forward-thinking approach helps the industry align with global sustainability goals while maintaining operational effectiveness.

Facilitating Collaboration Across Teams

Another often-overlooked benefit of digital twin technology is its ability to facilitate collaboration among different teams. Engineers, geologists, operations teams, and environmental experts can all access the same digital model, providing a unified platform for data sharing and decision-making.

For example, geologists can share insights on subsurface conditions, while drilling engineers can use this information to adjust drilling techniques in real-time. Environmental experts can then evaluate the potential impact of the drilling strategy and suggest modifications to minimize environmental damage. This level of cross-departmental collaboration leads to more informed decisions and ensures that both safety and sustainability objectives are met.

Digital twin technology is revolutionizing the oil and gas industry by transforming how drilling operations are conducted. From enhancing safety and efficiency to reducing environmental impact, digital twins provide a powerful platform for innovation. By leveraging real-time data, predictive analytics, and simulation capabilities, companies can optimize their drilling practices, reduce operational risks, and move toward a more sustainable future.

As the industry continues to evolve, digital twin technology will be a critical tool for companies looking to stay competitive and meet the growing demands for efficiency, safety, and environmental responsibility. In an era where operational excellence and sustainability go hand in hand, digital twins are leading the way forward.